When Jaguar shuts down its factories in June of this year, that will be the end of internal combustion engine production for the brand.

In fact, it will be the end of production, full stop. At least until the new Jaguar EVs come online, if they do. We’re still not convinced that Tata won’t pull the plug on them at the last minute, like Thierry Bolloré did with the electric XJ back in 2021.

Considering the current slowing down of EV sales, especially in the U.S., we’re not too hopeful.

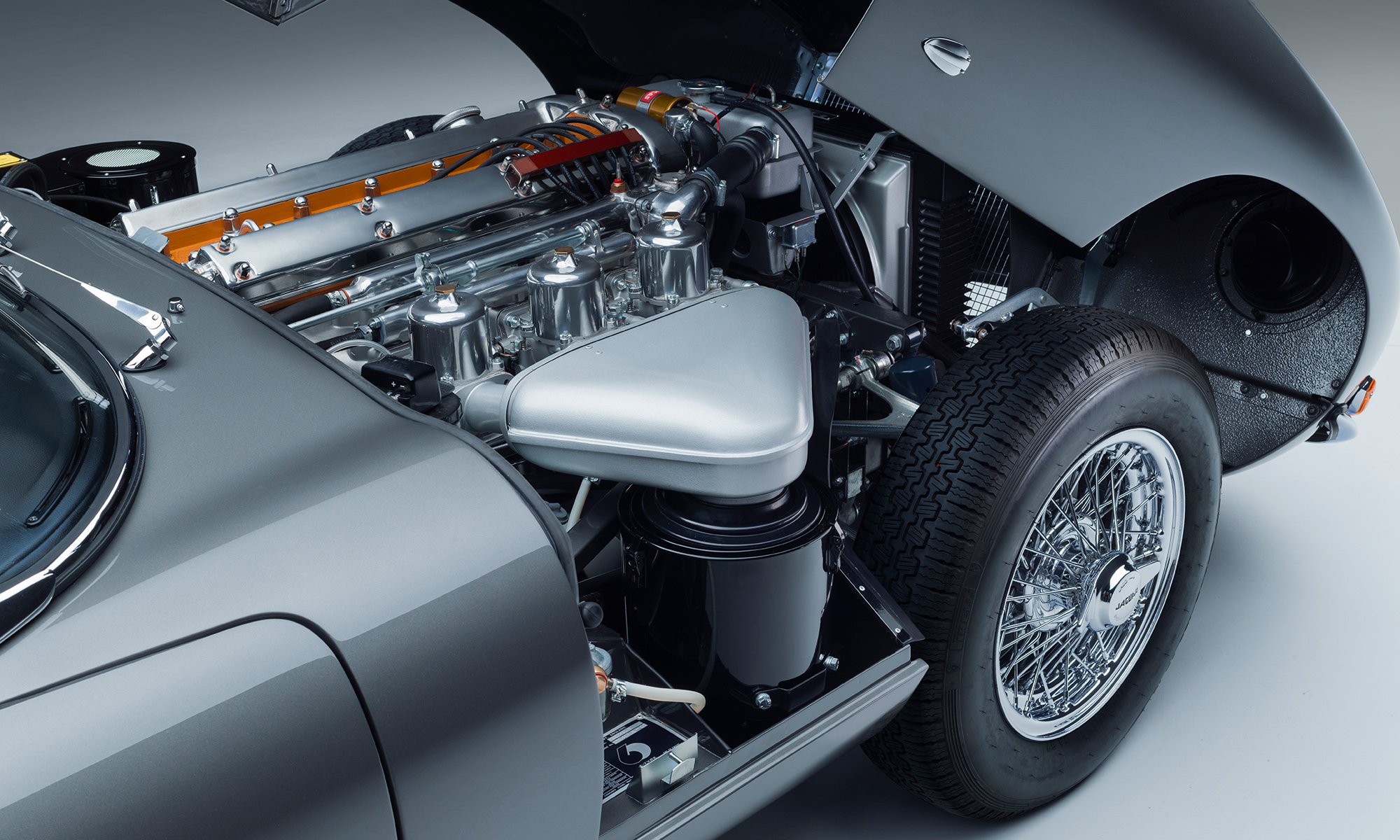

Besides, we’ve always claimed that Jaguar engines should have cylinders in multiples of six. We never expected to see that become zero times six. Nor were we quite ready for one and one third times six or two thirds times six either, but that’s a different story.

As we’ve previously reported, Jaguar will transition to an all-electric lineup in 2025. You’ll still be able to purchase a new Jaguar until then though, if everything goes according to plan:

“The majority of our products cease production in June, but they will be on sale for a much longer time, we will have a production schedule that enables us to have a continuous supply of vehicles until the new cars come … We’re trying to time it so we have enough volume to take us through to the launch of the new product and have a clean handover. Whether it will be as perfectly planned as that, we’ll see – maybe we’ll sell out more quickly, or maybe it will take a little longer to sell through the current inventory. But the plan is to sunset the current product portfolio and then launch the new ones.”

– Joe Eberhardt, JLR’s North American President and CEO, to Road & Track

If you’d like us to translate the corporate speak for you, we think he’s saying “We’ve given up on the current models.”

We understand and agree, with the exception of the F-Type. It was a gorgeous car, and even a really good car, one that deserved to see higher sales numbers than it did. Desperately in need of a bottoms-up refresh after 10 years in production, but still a worthy successor to the E-Type. There, we said it.

But the rest of the lineup? Good riddance.

As far as we know, there are still new F-Types available, so grab one while you can. Rejoice in the glorious soundtrack of a V8 engine that has been refined to damn near perfection. Find yourself an open road with some twisty bits and set it free. Let it do what it was born to do, this beautiful last of its kind.

Perhaps gone, but never forgotten.